- Cart

- |

- Personal Center

- |

Super-smooth Ultra-high Reflectivity Concave Mirror 1530-1600nm 12.7x6.35mm

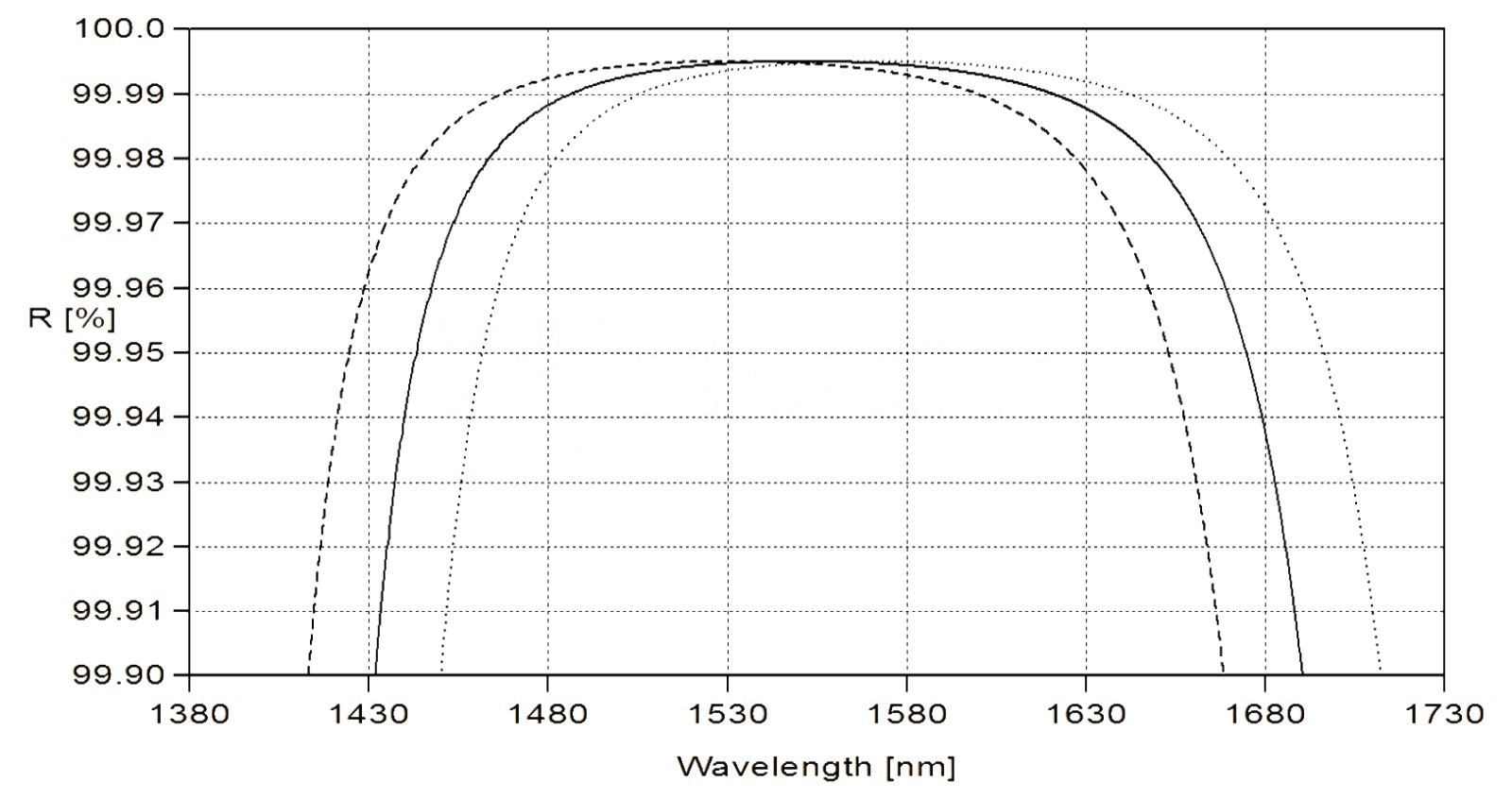

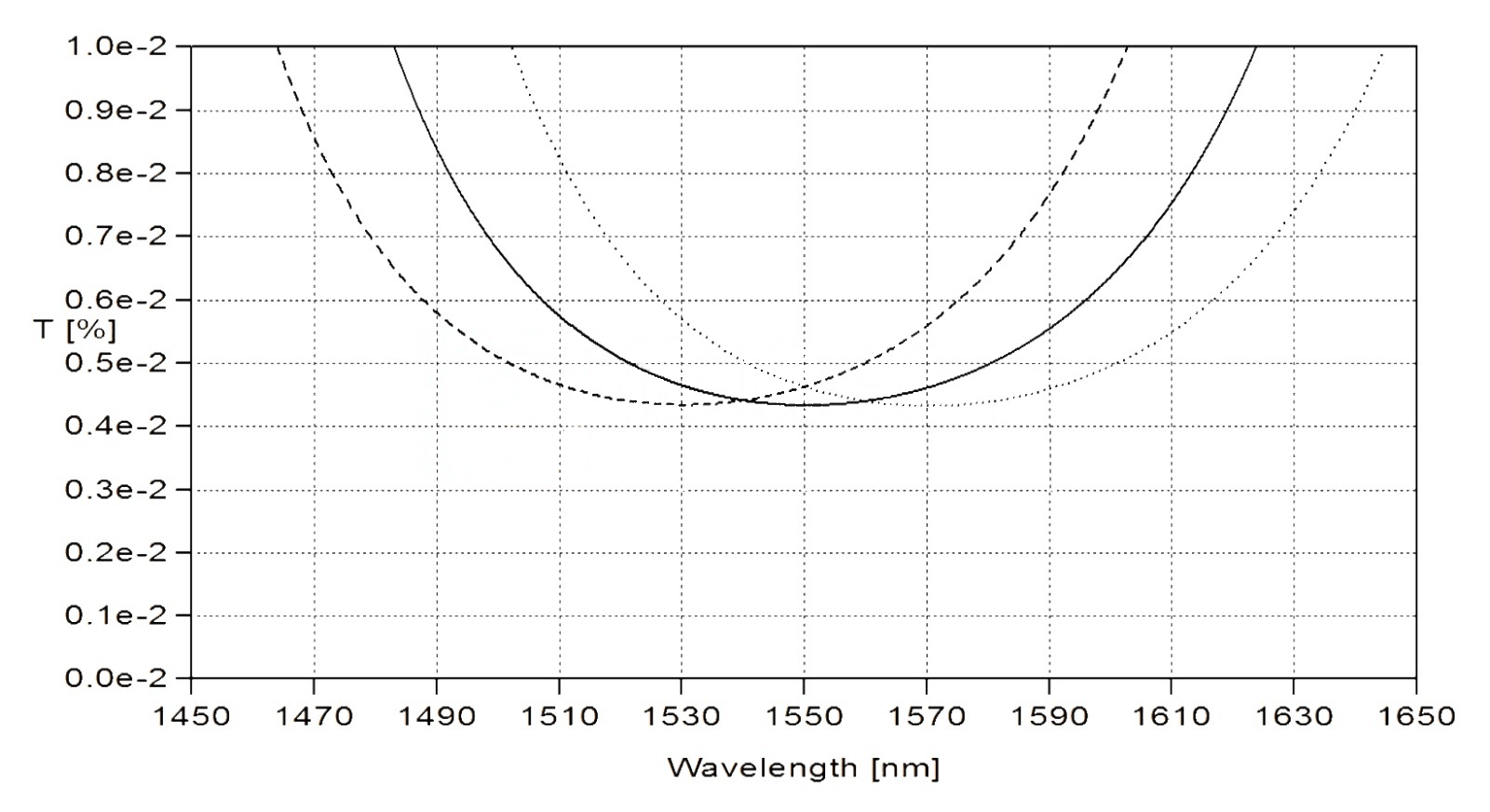

The so-called super mirrors, used in ring laser gyroscopes or certain scientific applications, require coating optical components with extremely low loss (i.e., absorption and scattering). These mirrors also exhibit a maximum reflectivity of R > 99.998% and total losses < 10 ppm. Idealphotonics uses a German-improved IBS machine, which is capable of producing coatings on ultra-polished substrates. The cleanliness of the machine and environment is maintained in a dedicated clean room, where extensive substrate pre-treatment and post-treatment processes are carried out. Measurement devices for inspection, such as white light profilometers and high-resolution microscopes (up to x 1000), are in place. Customized cavity decay setups allow for the determination of reflectivity and reference losses with accuracy up to four decimal places.

Product features:Extremely high reflectivity (R > 99.99% in the visible and near-infrared spectrum range, with R > 99.999% confirmed at several wavelengths between 1000-1600 nm). 、 The center wavelength can be customized. 、 All mirrors used for CRD experiments are equipped with anti-reflective coatings on the back. 、 They feature flat and spherical curved fused silica substrates with high-quality polishing, and an RMS roughness of ≤ 1.5 Å.

Part Number:--

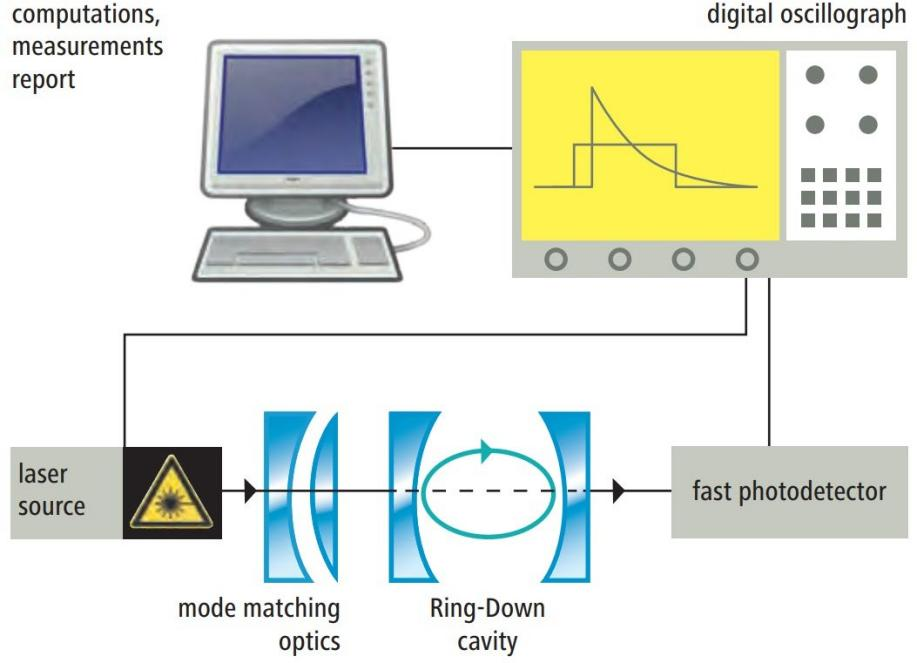

Application area:Laser gyroscope 、 CRD cavity decay system design 、 Optical path diagnostics

Add to Cart Consult Favorite

Main Parameters

The Fraunhofer Institute for Applied Optics and Precision Engineering in Jena measured the total backscatter (TSB, as described in ISO 13696) of our currently produced 633nm super mirrors, achieving a TSB value of 1.1 ppm. A typical absorption and residual transmission rate of < 15 ppm corresponds to a reflectance of at least 99.998%. For longer wavelengths, this can even reach 99.999%, which is very close to the perfect laser mirror with R = 100%.

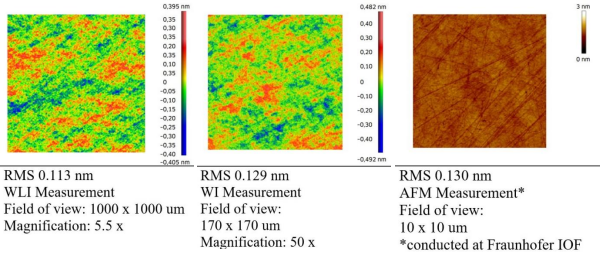

The results have been confirmed by our internal cavity decay setup and scattering measurements. For the above values, ultra-polished substrates with a surface roughness of < 1 Å rms are essential. Their quality was checked with a white light profiler. Below are some measurement values:

Scatter TSB | Absorption | Reflection CRD | |

HR 532 nm / 0° | 4.9 ppm 1) (int. ARS) | 10.2 ppm 2) | > 99.997% 2) (T~5 ppm) |

HR 633 nm / 0° | 1.1 ppm 1) | > 99.998% (T~5 ppm) | |

HR 1064 nm / 0° | (< 1 ppm) 3) | < 2 ppm 4) | > 99.999% (T~5 ppm) |

HR 2940 nm / 0° | 24 ±12 ppm 6) | 99.994% 5) (T=36 ppm) | |

1) Measured at IOF Jena; 2) Measured at LZH; 3) Calculated from surface roughness; 4) Measured at ILT Aachen;5) measured by customer; 6) 1-R-T

Material | Infrared-grade fused silica Infrasil |

Shape | Round |

Diameter(Ø) | 12.7,25.4 mm ,50.8(-0.1 mm) |

Thickness (t) | 6.35 mm (±0.1 mm) |

Edge Thickness | 6.35 mm |

Parallelism | 5’ |

Guaranteed Roughness | Flatness | Availability | |

Premium | RMS<0.2 nm*(<2Å) | <λ/20 | Ø12.7-25 mm always 2,000 pcs.on stock (various radii and plane) |

superpolished | RMS<0.1 nm*(<1Å) | <λ/10 | on request |

* Tested with Zygo NewView 9000 within sample length 3- 1000 um

Optical Parameters | Front (S2) | Optical Parameters | Back (S1) |

Shape | Concave | Shape | Plain |

Radius of Curvature | 1,000 mm (±1 %) | Chamfer | 0.3 mm (±0.1 mm) |

Chamfer | 0.3 mm (±0.1 mm) | Test Area Øe | 20 |

Test Area Øe | 20 | Surface Tolerance | 3/0.2(0.2) [L/10 @546.1nm] |

Surface Tolerance | 3/-(0.2) [L/10 reg. @546.1nm] | Cleanliness | 5/2x0.04; L1x0.004 |

Cleanliness | 5/2x0.04; L1x0.004 |

Test Plan

Related Tests

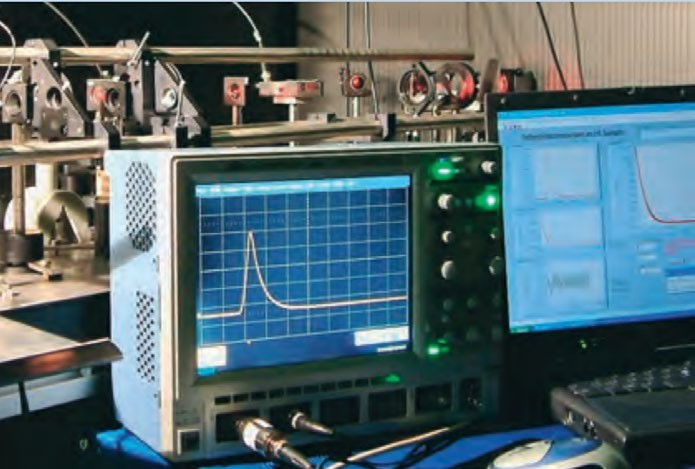

Direct Measurement of Optical Loss

Internal Testing Equipment

|  |  |

Optical Surface Quality Analysis | Automated Roughness Testing | Laser Loss Testing |

The low roughness values are consistently maintained across all spatial frequencies. Exemplary roughness measurements of Premium substrates at different magnifications demonstrate high quality regardless of the sampling length.

Customized product parameters example

Ordering info

CRD- □□□□-☆-▽

□□□□: Size

126: Diameter: 12.7mm × Thickness: 6.35mm

256: Diameter: 25.4mm × Thickness: 6.35mm

508: Diameter: 50.8mm × Thickness: 8mm (other sizes available)

☆ : Reflectivity

39: > 99.9%

49: > 99.99%

▽: Operation Wavelength Range

760: 760nm

980: 980nm

1064: 1064nm

1512: 1512nm

2000: 2000nm

2327: 2327nm

Wavelength | Substrate material | Diameter(Inch) | curvature | reflectivity | angle of incidence | optical wedge | PN # |

2327 | Infrasil 302 | 0.5" | 1m ROC | > 99.99 % | 0 | None | CRD-126-49-2327 |

2004 | Infrasil 302 | 1.0" | 1m ROC | > 99.99 % | 0 | None | CRD-246-49-2004 |

2050 | Infrasil 302 | 0.5" | 1m ROC | > 99.99 % | 0 | None | CRD-126-49-2050 |

1742 | Infrasil 302 | 0.5" | 1m ROC | > 99.99 % | 0 | None | CRD-126-49-1742 |

1650 | Corning 7980 | 0.5" | 1m ROC | > 99.99 % | 0 | None | CRD-126-49-1650 |

1600 | Corning 7980 | 0.5" | 1m ROC | > 99.99 % | 0 | None | CRD-126-49-1600 |

1550 | Corning 7980 | 0.5" | 1m ROC | >99.99% | 0 | None | CRD-126-49-1550 |

1550 | Corning 7980 | 1.0" | 1m ROC | >99.99% | 0 | None | CRD-246-49-1550 |

1512 | Corning 7980 | 0.5" | 1m ROC | >99.99% | 0 | None | CRD-126-49-1512 |

1434 | Infrasil 302 | 1.0" | 1m ROC | >99.99% | 0 | None | CRD-246-49-1434 |

0760 | Corning 7980 | 0.5" | 1m ROC | > 99.995 % | 0 | None | CRD-126-49-0760 |

0760 | Corning 7980 | 1.0" | 1m ROC | > 99.995 % | 0 | None | CRD-126-49-0760 |

1392 | Corning 7980 | 0.5" | 1m ROC | > 99.99 % | 0 | 30ʹ | CRD-126-49-1392 |

0633 | Corning 7980 | 1.0" | 1m ROC | > 99.99 % | 0 | None | CRD-246-49-0633 |

1064 | Corning 7980 | 1.0" | 1m ROC | > 99.99 % | 0 | None | CRD-246-49-1064 |

--

⇪