- Cart

- |

- Personal Center

- |

IR Polished Al2O3 Circular Sapphire Window 0.17-5.5μm 25.4x1.0m

Sapphire (Al2O3) is highly regarded for its extreme toughness and strength, making it an ideal material for optical windows across the UV, VIS, and NIR spectral ranges. Sapphire can be grown using different methods. The Verneuil and Czochralski processes are commonly used for standard-grade sapphire materials. Higher-quality sapphire, used for electronic substrates, is typically grown by the Kyropulos method, offering exceptionally high purity and excellent UV transmission properties. In the IR spectrum, sapphire's use is generally limited to around 5μm, with few issues encountered at optical grades. In the UV range, care must be taken when observing its transmission from 140nm to 240nm, as it is highly sensitive to impurities and voids. Large sapphire crystals can be made by color-band growth. Sapphire exhibits slight birefringence, and IR windows are typically cut randomly from the crystal. For specific birefringence applications, an orientation can be selected, where the optical axis is at a 90-degree angle to the surface, referred to as "zero-degree" material. Synthetic optical sapphire is colorless. *Note: Actual thermal expansion values may vary across manufacturers.

Product features:

Part Number:--

Application area:

Add to Cart Consult Favorite

General Parameters

Transmission Range | 0.17~5.5μm |

Refractive Index | No 1.75449; Ne 1.74663(1.06μm)(1) |

Reflection Loss | 14% at 1.06μm |

Absorption Coefficient | 0.3×10-3cm-1 at 2.4μm(2) |

Absorption Peak | 13.5μm |

dn / dT: | 13.4×10-6(0.546μm)(3) |

dn /dμ= 0: | 1.5μm |

Density | 3.97g/cm3 |

Melting Point | 2040℃ |

Thermal Conductivity | 27.21W m-1 K-1 at 300K |

Thermal Expansion | 5.6(para)& 5.0(perp)×10-6 / K * |

Hardness | Knoop 2000 with 2000g indenter |

Specific Heat Capacity | 763JKg-1 K-1(293K)(4) |

Dielectric Constant | 11.5(para)9.4(perp)at 1MHz |

Young's Modulus (E) | 335GPa |

Shear Modulus (G) | 148.1GPa |

Bulk Modulus (K) | 240GPa |

Elastic Modulus | C11 = 496 C12 = 164 C13 = 115 C33 = 498 C44 = 148 |

Apparent Elastic Limit | 300 MPa(45,000 psi) |

Poisson’s Ratio | 0.25 |

Solubility | 98×10-6g / 100g water |

Molecular Weight | 101.96 |

Class/Structure:(hex),R3c | Trigonal(hex),R3c |

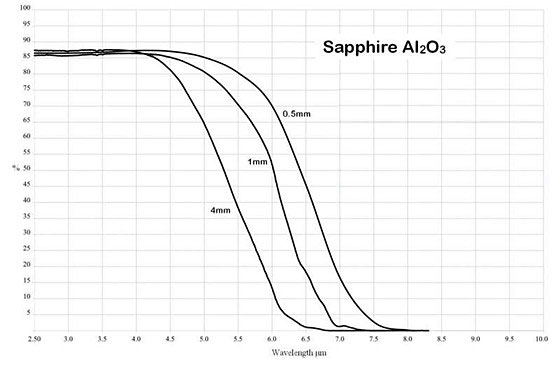

Spectral Transmission Curve

Refractive Index No = Ordinary Ray,Ne = Extraordinary Ray)

um | No | Ne | um | No | Ne | um | No | Ne |

0.193 | 1.9288 | 1.9174 | 0.213 | 1.8890 | 1.8784 | 0.222 | 1.8754 | 1.8650 |

0.226 | 1.8702 | 1.8599 | 0.244 | 1.8506 | 1.8407 | 0.248 | 1.8470 | 1.8372 |

0.257 | 1.8393 | 1.8297 | 0.266 | 1.8330 | 1.8236 | 0.280 | 1.8244 | 1.8151 |

0.308 | 1.8110 | 1.8020 | 0.325 | 1.8047 | 1.7958 | 0.337 | 1.8001 | 1.7921 |

0.351 | 1.7969 | 1.7882 | 0.355 | 1.7960 | 1.7883 | 0.442 | 1.7804 | 1.7721 |

0.458 | 1.7784 | 1.7702 | 0.488 | 1.7753 | 1.7671 | 0.515 | 1.7730 | 1.7649 |

0.532 | 1.7717 | 1.7636 | 0.590 | 1.7680 | 1.7600 | 0.633 | 1.7659 | 1.7579 |

0.670 | 1.7643 | 1.7563 | 0.694 | 1.7634 | 1.7554 | 0.755 | 1.7614 | 1.7535 |

0.780 | 1.7607 | 1.7527 | 0.800 | 1.7601 | 1.7522 | 0.820 | 1.7596 | 1.7517 |

0.980 | 1.7561 | 1.7482 | 1.064 | 1.7545 | 1.7466 | 1.320 | 1.7501 | 1.7423 |

1.550 | 1.7462 | 1.7384 | 2.010 | 1.7375 | 1.7297 | 2.249 | 1.7323 | 1.7243 |

2.703 | 1.719 | 1.711 | 2.941 | 1.712 | 1.711 | 3.333 | 1.701 | 1.693 |

3.704 | 1.687 | 1.679 | 4.000 | 1.674 | 1.666 | 4.348 | 1.658 | 1.65 |

4.762 | 1.636 | 1.628 | 5.000 | 1.623 | 1.615 | 5.263 | 1.607 | 1.599 |

Ordering Info

PN# | Specifications(D×L) | Orientation | Application Range |

SAPP10-2 | 10.0×2.0mm | Random | IR |

SAPP12-1 | 12.0×1.0mm | Random | IR |

SAPP12-2 | 12.0×2.0mm | Random | IR |

SAPP12-4 | 12.0×4.0mm | Random | IR |

SAPP15-2 | 15.0×2.0mm | Random | IR |

SAPP18-4 | 18.0×4.0mm | Random | IR |

SAPP20-2 | 20.0×2.0mm | Random | IR |

SAPP25-0.5 | 25.0×0.5mm | Random | IR |

SAPP25-1 | 25.0×1.0mm | Random | IR |

SAPP25-2 | 25.0×2.0mm | Random | IR |

SAPP25.4-1 | 25.4×1.0mm | Random | IR |

SAPP26-1 | 26.0×1.0mm | Random | IR |

SAPP35-2 | 35.0×2.0mm | Random | IR |

About Crystal Cutting

Sapphire is slightly birefringent and so for critical optical or mechanical applications, the windows should be specified as 'zero degree', or 'c-cut', meaning that the optical axis of the material should be perpendicular to the plane of the window. Ifunspecified, the component will be of'random' cut, but its worth noting that this is nearly always 60° to the optic axis as this is the 'softest' direction for the saw. Note that all sapphire is always single crystal, sub-grains are always avoided in the cut.

C-plane (0,0,0,1) = Z-cut

A-plane (1,1,-2,0) = Y-cut

M-Plane (1,0,-1,0) = X-cut R-Plane (1,0,-1,0)

Manufacturers seem unable to agree on the thermal expansion coefficient of sapphire, figures from 5.6 to 8.4 x 10-6 K are given. While there may be some variation due to the method of growth, and certainly due to the axis of cut, this variation is inexplicable.

--

⇪