- Cart

- |

- Personal Center

- |

950-1650nm InGaAs Detector with Dual TEC, Photodiode Φ1000µm

The P97MXXT2 series unit InGaAs detector consists mainly of a P-I-N structure InGaAs photosensitive chip, transition electrode plate, temperature sensor, and a dual-stage thermoelectric cooler (TEC), all housed in a TO package. This user manual specifically covers this series of products.

Product features:

Part Number:--

Application area:

Add to Cart Consult Favorite

Main Parameters of the Detector

Structural Parameters

PN# | Package | Cooling Type | Active Area (μm) | Chip Size (μm) | Electrode Size (μm) |

P97M03T2-A | TO Package | Dual-stage Cooling | Φ300 | 850×850 | 140×180 |

P97M05T2-A | Φ500 | 1000×1000 | 140×180 | ||

P97M10T2-A | Φ1000 | 1410×1410 | 140×180 | ||

P97M20T2-A | Φ2000 | 2560×2560 | 280×360 | ||

P97M30T2-A | Φ3000 | 3560×3560 | 320×480 |

Optoelectrical Parameters

PN# | Test Temperature Tch (℃) | Spectral Response Range λ (μm) | Dark Current ID (nA) | Junction Capacitance C (f=1MHz, VR=0V) (pF) | |

VR= 1V | VR=5V | ||||

P97M03T 2-A | 25 | 0.95±0.05 to1.65±0.05

Peak Value λP= 1.55 | 0. 1 | 0.5 | 50 |

P97M05T 2-A | 0.25 | 1 | 100 | ||

P97M10T 2-A | 1 | 4 | 300 | ||

P97M20T 2-A | 4 | 10 | 800 | ||

P97M30T 2-A | 10 | 40 | 2000 | ||

PN# | Peak Responsivity S (A/W) | Shunt Resistance Rsh (VR=10mV) (MΩ) | Peak Detectivity D* (cm·Hz^(1/2)/W) | Noise Equivalent Power NEP (W/Hz^(1/2)) |

P97M03T2-A | 1.0 | 3500 | 3×1012 | 8.9 × 10-15 |

P97M05T2-A | 1000 | 1.5 × 10-14 | ||

P97M10T2-A | 300 | 3.0×10-14 | ||

P97M20T2-A | 80 | 5.9 × 10-14 | ||

P97M30T2-A | 40 | 8.9 × 10-14 |

Mechanical Structure and Electrical Interface

The detector has dimensions of φ15.3mm × 10mm (excluding the pins). The bottom surface of the shell has 8 pins with a diameter of 0.45mm and a pin length of 13.5mm, which are used for TEC power supply, temperature sensor signal reading, and detector signal output. The design distance from the light-sensitive surface to the bottom of the window is 2.3mm, and the design distance from the mounting surface (i.e., the bottom of the shell) is 6.2mm. The window material is sapphire, with a thickness of 0.5mm, and the transparent area has a design diameter of φ9mm. The center of the light-sensitive surface is located at the center of the detector, with a positional offset of less than 0.3mm. The mechanical interface appearance and dimensions, as well as the optical and electrical interfaces, are shown in the figure.

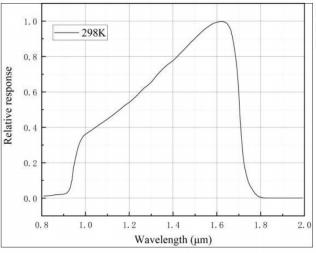

Response Spectrum (Typical Value)

Thermal Parameters

Operating Environment

Parameter | Typical Value |

Operating Temperature(℃) | -45~+55 |

Storage Temperature(℃) | -50~+60 |

Thermoelectric Cooler (TEC) Characteristics

The detector integrates a two-stage thermoelectric cooler (TEC), with the center of the heat dissipation surface coinciding with the center of the detector's bottom surface. The heat dissipation area should be ≥ 6mm × 6mm. The performance parameters are as follows:

Performance Specifications | Value |

Max. Thermal Load Power (Qmax/W) | 0.93W |

Max. Allowed Load Current (ITEC-max/A) | 1A |

Max. Allowed Load Voltage (VTEC-max/V) | 2V |

Temperature Monitoring Module Characteristics

The detector uses a thermistor as the temperature monitoring module. The resistance values corresponding to different temperatures within the operating range are shown in the table below:

Temperature ( ℃ ) | Resistance( kΩ) | Temperature ( ℃ ) | Resistance( kΩ) |

-65 | 94.270 | -15 | 6.909 |

-60 | 69.290 | -10 | 5.587 |

-55 | 51.500 | -5 | 4.549 |

-50 | 38.700 | 0 | 3.729 |

-45 | 29.400 | 5 | 3.075 |

-40 | 22.560 | 10 | 2.55 |

-35 | 17.490 | 15 | 2. 126 |

-30 | 13.690 | 20 | 1.782 |

-25 | 10.810 | 25 | 1.5 |

-20 | 8.608 | 30 | 1.268 |

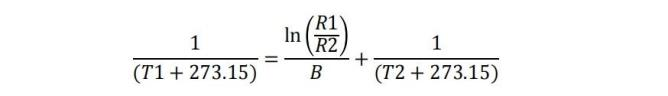

Thermistor Resistance-Temperature Relationship Formula

T1: Test target temperature, unit: °C;

T2: Reference point temperature, unit: °C. The typical reference temperatures within the range of -2070°C are 10°C or 40°C. Choose a reference temperature close to the target temperature;

R1: Thermistor resistance corresponding to T1, unit: kΩ;

R2: Thermistor resistance corresponding to T2, unit: kΩ;

B: The typical B10/40 value within -2070°C is 3019.6±60.

Notes:

a) During the installation of the TEC, attention must be paid to the additional resistance introduced by external electrical structures. If the added resistance exceeds 10% of the TEC resistance, the I-V curve needs to be recalibrated.

b) It is recommended to connect the TEC using a low-resistance method. If soldering is required, short-circuit grounding protection should be applied. The soldering temperature should be ≤250°C, and the soldering time should be <10s.

c) If higher measurement accuracy is required within a small temperature range, the B value can be calculated according to specific requirements.

d) Before turning on the TEC, ensure that the temperature monitoring module is functioning correctly, that the cooling surface has sufficient contact with the heatsink, and that the cooling surface area meets the required size. The heatsink should also be operational. The TEC should not be turned on without an installed or functioning heatsink.

e) When turning on the TEC for the first time, start with 0A or 0V, gradually increase the current or voltage while monitoring the temperature changes until the preset temperature is reached.

f) Since the performance of the detector is temperature-dependent, the TEC should be turned on to stabilize the temperature before the detector is turned on. It is not recommended to operate the detector in an environment with fluctuating temperatures.

g) When the detector is not operating, the TEC should be powered off to extend its service life.

h) The cooling effect of the detector is influenced by the ambient temperature, power supply performance, and cooling system status. It is recommended to design the cooling system appropriately based on the user's environment and performance requirements.

--

⇪