- Cart

- |

- Personal Center

- |

1310/1550 nm Multi-function Polarization Maintaining Fiber Fused Taper System IPCS-5000-P

The IPCS-5000-P full-function fiber taper system is a highly automated production system jointly developed by Idealphotonics and UBC in Canada, integrating multiple technologies such as optics, electronics, precision machinery, and computers, as well as multiple functions such as production, detection, and control. In addition to providing the functions of an ordinary fiber taper machine, the machine can also be upgraded to a polarization-maintaining fiber taper machine, a large-core multimode fiber taper machine, a tapered fiber stretching system, etc. according to the customer's research requirements. It is a powerful platform for you to engage in the development of core devices such as fiber splitters, wavelength division multiplexers, communication market development, fiber sensors and fiber lasers, biomedicine, and laser micro-nano research. (Optional 1310/1550 nm dual-wavelength desktop detection light source (1 mW), 2um desktop detection light source; detector extended InGaAs 1100-2400 nm)

Product features:

Part Number:--

Application area:

Add to Cart Consult Favorite

Summary of common problems with polarization-maintaining taper machines:

1. Does this working wavelength involve 1310, 1550 band light sources?

No, we can provide light sources in the 1310 or 1550 bands

2. Is this model capable of polarization-maintaining and multi-mode large core diameter tapers?

Yes

3. Is the fixture also included? Or do I need to buy it again?

Yes, it is included, no need to buy it again

4. What is the maximum core diameter?

200um. Customized fixtures are required for tapers greater than 200um, which need to be purchased separately.

5. What are the fixtures that come with the kit?

125/250um fixtures. This type of 50/100/200um can be used

6. How do you control the polarization in the polarization-maintaining taper to prevent it from rotating?

It is also vacuum adsorption. It is difficult to control the polarization state in polarization-maintaining tapers. The polarization state can only be checked after the taper is completed.

Software features

The software developed by the all-English intelligent UBC team can optimize parameters according to the specific experimental requirements of customers

The amplitude of the flame head scan can be set according to the required stretching length and cone shape

The stretching speed can be changed according to the change of stretching length and cone temperature.

The flow rate of hydrogen and oxygen can be changed according to the stretching length and stretching speed

The intelligent energy software storage memory function facilitates users to call the optimal production data

Software interface GUI

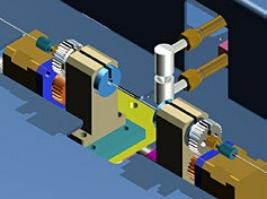

Hardware features (different hardware designs are selected according to the differences in the developed devices)

The system adopts an external hydrogen and internal oxygen mixed flame head to improve the temperature instability caused by the original upper and lower oxygen addition, and improve the heating temperature and heating uniformity

The extended InGaAs detector is used to facilitate customers to develop and produce 2um devices

The Japanese sliding wire guide + precision ball screw is used to ensure the maximum single-sided stretching range of 40mm

The American Alicat gas flow meter and driver are used to ensure the stability of the flame temperature during the stretching process

Special fixtures can be designed according to the core diameter of the optical fiber used

Different detectors are selected according to the working wavelength of the developed device

According to the core diameter of the optical fiber used, a flow meter with a suitable range is selected

Taiwan's sliding wire guide + precision ball screw is used to ensure the maximum heating temperature

Different flame heads and fixing methods are designed according to the requirements of optical fiber taper

On the basis of the customized optical fiber stretching platform, the ordinary optical fiber taper function is opened to realize the "one machine multi-function open system"

CCD visual system (optional) to assist in observing the optical fiber axis/ The process of taper pulling

(C) Compared with general machines (as shown below)

|  |

Ordinary Fiber Fused Taper Machine | Idealphotonics Fiber Fused Taper Machine |

The brushed shell has an excellent industrial texture

The working platform is 1/3 longer than ordinary machines, ensuring the convenience of secondary upgrades

Equipped with a precision ball screw (pitch 2mm) to ensure the axial stretching accuracy and stable movement speed of the machine

In addition to the manufacturing of the taper platform, we can provide users with a real "one-basket" service in the selection of special optical fibers, packaging materials and finished product testing instruments

Cone platform indicator

1.Normally SM Fiber Coupler

Operating wavelength | 1310nm, 1550nm, 1310/1550nm |

Additional loss | <0.2 dB |

Insection loss | <3.2 dB |

Bandwidth | +/-20nm, +/-40nm |

Splitting ratio | 1—99%, Error:±2% |

Packaging size | 30-40mm |

Curing method | Thermosetting adhesive |

Stand 50/12.5um, 60/125um Multimode fiber devices and WDM can be used interchangeably. | |

B.PM Fiber Coupler

Working wavelength | 1310 nm, 1550 nm |

Extinction ratio | ≥ 20dB, some can reach 25dB |

Additional loss | 0.2-0.5dB (domestic or imported Panda polarization-maintaining matching fiber) |

Package size | 30-40 mm |

Split ratio | 50: 50±5% (splitting ratio can be set arbitrarily) |

Device structure | 1x2, 2x2 and 1x3 |

Curing method | Thermosetting adhesive |

Used optical fiber | 125/250um, 80/165um Panda PM fiber (special fixture) |

C.N x M Large-core Diameter Multimode Fiber Beam Combiner

N | 2,3,4......7 or (N+1) |

Fiber core diameter | 50um, 100um, 200um, 400um, 600um... |

Fiber | N.A 0.11, 0.22, 0.37, 0.48 |

Device carrying power | W level |

According to the thickness of the optical fiber core diameter, the flow meter range is improved and the size of the optical fiber clamp is designed. | |

D.Fiber Single Cone

SM Fiber | Core: 9 um to 1 um, even less |

PM Fiber | Core 400 um to 62.5 um, core 600 um to 200 um, even less |

Main device indicators

Flame heating unit | |

Flame axial swing | 0-21 mm |

Movement rate | 0-4 mm/s continuously adjustable |

Combustion gas | Hydrogen (or Oxygen) |

Hydrogen flow rate | 0-800 SCCM |

Oxygen flow rate | 0-400 SCCM |

Optical components | |

Detector | Extended InGaAs: 1100-2400 nm |

Optional | Si: 400-1000 nm, Ge:1000-1800 nm |

Light Source | Optional: 1310/1550 nm dual-wavelength desktop detection light source (1 mW), 2um desktop detection light source (device development around 2um) |

UV Detector Optional | UV lamp is optional, customers need to research and manufacture UV band devices |

Main device | |

Taper platform stretching accuracy | 0.15 μm |

Taper platform stretching speed | 0.15—12000 μm/s |

Maximum taper platform stretching distance | 55 mm |

Fiber that can be clamped | 0.1—0.5 mm |

Minimum distance between clamps | 30mm |

Workbench shape and dimensions | 21.65”x 16”x 9.65”(550 x 405 x 245mm) |

Weight | 70lb (31.5kg) Approx. |

Power supply | 100-240V, 50/60Hz, 150Watt |

Principle of fused taper

The optical fiber taper system uses vacuum adsorption and special fixtures to position and clamp two or more optical fibers on the optical platform, and rotates the two or more bare fibers without coating in a certain way, brings the axes (only for polarization-maintaining fibers) closer, heats and melts them under hydrogen-oxygen flame, and stretches them to both sides at a certain speed, eventually forming a special waveguide structure in the form of a double cone in the heating area, thereby achieving the purpose of making various optical fiber coupling devices and optical fiber tapers.

Tapered Fiber Testing

Tapered fiber test results

Micrometer-level optical fiber data measured by power microscope

Tapered Fiber Placement

How to place tapered fiber

--

⇪